What should buyers ask before picking a liquid filling machine? They should think about product type and how much they need to make. Buyers should also look at automation and the filling method. It is important to check if the machine fits the containers. They should see if it can work with other machines. Customization, maintenance, and budget are also important. These questions help buyers compare different filling machines. A checklist helps users when they look at each machine or talk to suppliers. Picking the right machine for your needs makes sure it works well. The right choice stops expensive mistakes and helps you do well for a long time with liquid filling machines.

Key Takeaways

You need to know your liquid type and container size. This helps you pick the right filling machine for your product and bottles.

Match your production speed and automation level to what you need now. Think about your future growth plans for the best results.

Pick the filling method that works for your liquid’s thickness and accuracy needs. This helps reduce waste and makes quality better.

Make sure the machine works well with your production line. Think about custom features to help make things faster and cleaner.

Plan to do regular maintenance and budget your money wisely. This keeps machines working longer and saves money over time.

Product Compatibility

Product Type

When picking a bottle filling machine, you need to know your liquid. Some liquids are thin, like water or juice. Others are thick, like honey or cream. Each kind needs its own filling method. Thick liquids work best with positive displacement pump filling machines. These machines fill things like gels and pastes. Some products have pieces in them or make foam. These need special nozzles or mixing systems. Dangerous chemicals and medicines need machines that keep people safe. The table below matches product types with the best filling machines:

Product Characteristic | Description | Recommended Filling Technology |

Viscosity | Thin liquids (water, juice); thick liquids (lotions, sauces) | Gravity or overflow fillers for thin; piston or pump fillers for thick |

Particulates | Solids like pulp or herbs | Specialized nozzles or agitation systems |

Carbonation | Carbonated beverage | Counter-pressure filling systems |

Accuracy | Precise dosage needed | Volumetric or flow meter-based fillers |

Container Shape & Size | Irregular or oversized bottles | Adjustable nozzles, stabilizing guides |

Food filling machines must work with many products. They fill things like sauces and chunky soups. Bottle filling machines for drinks use counter-pressure systems. This keeps bubbles in the drink.

Container Size

The size of the container is very important. Some machines can fill many bottle sizes. This helps production move fast. It also means you do not need to change machines often. These machines help you make more products without stopping. Most commercial bottle filling machines fill from very small to large containers. The table below shows some size ranges:

Manufacturer | Container Size Range |

E-PAK Machinery | Fraction of an ounce to 5 gallons |

Accutek | 1 oz to 1.3 gallons |

Cozzoli | 0.37 to 157 ounces |

Oden Machinery | 1/4 ounce to 5 gallons |

Food filling machines and bottle filling machines work with bottles, jars, vials, and pouches. This makes sure each fill is correct and stops waste.

Production and Automation

Output Needs

Manufacturers need to know how many bottles they must fill each hour. This number helps them pick the best filling machines for their work. Small companies often use machines that fill 10 to 100 bottles each minute. Medium businesses may want a little more speed but stay close to this range. Big factories need much faster machines. Some can fill thousands of bottles every hour.

Scale | Average Output Capacity Range |

Small Scale | Up to 10-100 bottles per minute (BPM) |

Medium Scale | 10-100 BPM (customized for production needs) |

Large Scale | 1,000 to 24,000+ units per hour |

The kind of filling machine changes how many bottles you can fill. Manual machines are good for small jobs. Semi-automatic machines work for small or medium jobs. Inline filling machines can fill up to 200 bottles each minute. Rotary filling machines can fill up to 300 bottles each minute. Monobloc systems fill even more for very big jobs.

Automation Level

Automation changes how fast you can fill bottles and how many workers you need. Automatic filling machines can fill hundreds or thousands of bottles every hour. This helps companies make more products in less time. It also means you need fewer workers to run the machines.

Automation has more good points. It fills bottles more accurately, so there is less waste and fewer mistakes. Machines with automation can change between products quickly and keep working with little stopping. Modular systems let you add more machines as your company grows, without needing more workers.

When picking the right automation, think about your goals, space, and money. Manual machines are good for small businesses or new companies. Semi-automatic machines give a balance between speed and cost. Fully automatic systems are best for big factories that need to fill bottles fast and have room for large machines.

Filling Machine Technology

Filling Method

Manufacturers use different filling methods for different liquids. Each method works best with certain products. This helps the filling process stay safe and fast. The table below shows the main filling methods and what they are good for:

Filling Method | Principle / Mechanism | Suitable Products / Characteristics |

Gravity Filling | Liquid flows by weight without extra pressure | Thin, free-flowing liquids like water, juices; simple, easy to care for, gentle on product |

Piston Filling | Piston-cylinder pulls in and pushes out set amount | Thick products, creams, gels, pastes, products with pieces; very accurate and does the same thing every time |

Pump Filling | Uses pumps (gear, lobe, peristaltic) to move liquid with control | Works with many thicknesses, even chunky things like salsas, soups; can change flow speed easily |

Overflow Filling | Fills containers to the same level; extra liquid goes back to tank | Thin to medium thickness, foamy products; makes sure fill looks the same, good for clear bottles |

Vacuum Filling | Makes pressure difference to pull liquid into containers | Thick or sticky liquids like oils, syrups; keeps air out, stops spills and bubbles; good for gentle products |

Isobaric Filling | Makes pressure the same in container and tank to stop foam | Fizzy drinks like beer, soda, sparkling wine; keeps bubbles and quality safe |

Thin liquids work best with gravity or volumetric filling machines. These machines are easy to use and need little care. Piston filling machines are good for thick or chunky products like creams and sauces. They fill very accurately. Overflow filling machines keep the fill level the same, which looks nice in clear bottles. Vacuum filling machines help with thick or gentle liquids by stopping air bubbles and spills. Isobaric filling machines keep bubbles in fizzy drinks.

Liquid Filling Machine Types

There are many types of liquid filling machines. Each type is made for a special job. The main types are gravity, piston, pump, overflow, vacuum, and isobaric machines. Each one uses different parts and technology to fill containers. Important parts are a tank or hopper for holding liquid, a conveyor to move bottles, filling nozzles to pour, and a control panel for settings. Sensors check that bottles are filled right.

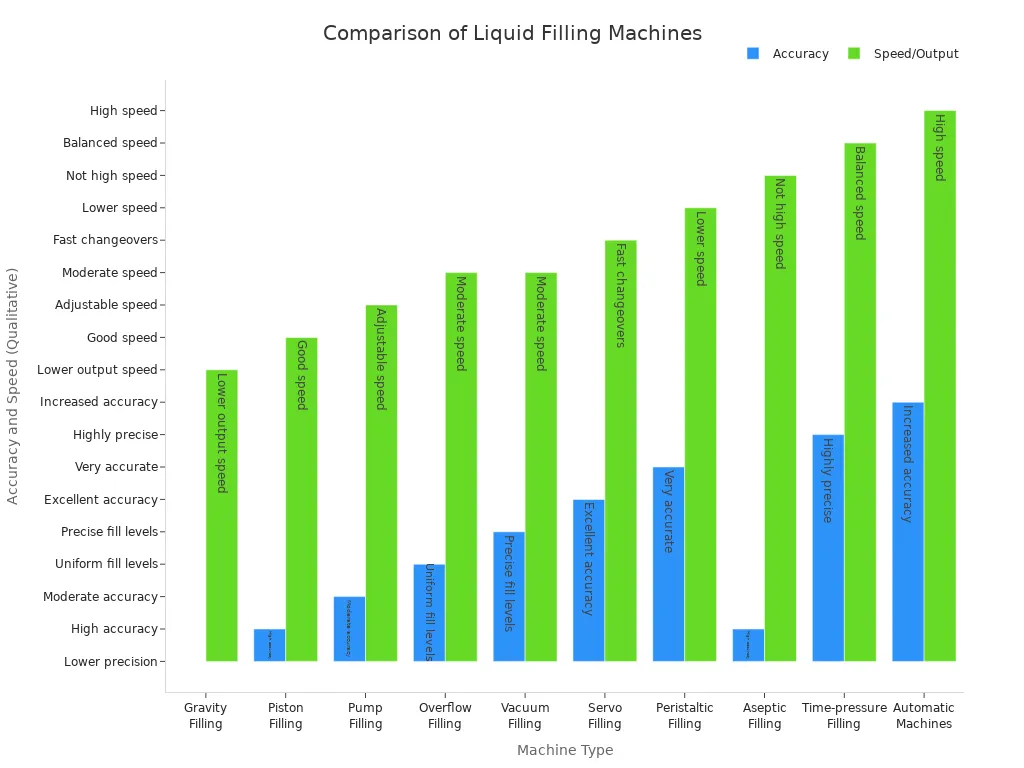

The chart below shows how each filling machine does with accuracy and speed:

Gravity filling machines are not as fast or accurate, so they are best for easy jobs. Piston filling machines are very accurate and work well with thick liquids. Pump filling machines can fill many kinds of liquids but may not be as exact. Overflow filling machines make sure bottles look full and even. Vacuum filling machines are good for gentle or thick products and fill very carefully. Automatic filling machines are fast and accurate, so they are great for big jobs.

Integration and Customization

Line Integration

Manufacturers can have problems when adding new liquid filling machines. They need to keep products clean and safe. This stops contamination and follows rules. Bottles and closures must be tested often. This helps avoid slowdowns in production. Workers watch machines and change settings. They do this to keep speed and accuracy balanced. Sometimes, products get thicker or thinner. Mixing and filling settings must change for this. Machines need to be set up just right. This stops leaks and keeps products safe. Checking machines often helps every batch stay the same. It also cuts down on waste.

Keep products safe with special filling and clean methods.

Test bottles and closures often so work does not stop.

Watch machines and change settings for speed and accuracy.

Change mixing and filling for thick or thin products.

Set up machines right to stop leaks and contamination.

Check batches to make sure they are always the same.

To make things work well, companies should:

Make sure filling machines work with other machines before and after.

Set up machines for different liquids and bottle shapes.

Use designs that are easy to clean and safe.

Teach workers to change settings quickly.

Update software and keep extra parts ready.

Ask suppliers for help and special solutions.

Custom Options

Every product and package can need something special. Customization helps companies get machines that fit their needs. Some machines use special nozzles or sensors for odd bottle shapes. Others change conveyor systems for different sizes. Custom features can be Clean-in-Place systems, special pumps, or parts that do not rust. These help keep things clean and make cleaning easier.

Filling Machine Type | Best Product Type | Custom Features and Benefits |

Overflow Filling Machines | Thin to medium liquids | Reuse product, fill exact amount, recirculation |

Time Gravity Filling | Thin liquids, steady flow | Timed valves, set intervals |

Net Weigh Filling | High-value, sold by weight | Weighs exactly, stops too much or too little |

Peristaltic Filling | Small amounts, thin liquids | No mixing, fills exactly |

Piston Filling | Thick, chunky products | Changes stroke, fills semi-solid things |

Servo Pump Filling | Liquid and semi-liquid | Fast changes, special nozzles, easy cleaning |

Brine Filling | Harsh, chunky liquids | Does not rust, does not clog |

Custom features can cost more at first. But they save money later by cutting waste and making cleaning faster. They also help fill bottles more accurately. Companies that pick the right custom features have fewer problems and better results over time.

Maintenance

Liquid filling machines need regular care to work well. Operators clean valves, nozzles, and filling parts every day. They check seals and gaskets for damage and replace them early. Lubricating motors and pumps keeps parts moving smoothly. Calibration makes sure fills are accurate, especially with different liquids. Nozzle care stops blockages and keeps fill levels right. Operators watch pressure and flow rates to keep output steady. Checking electrical systems helps prevent faults and keeps machines running. Software updates and diagnostic tools help machines work better. Operators look at motors and pumps for wear and plan repairs.

Maintenance schedules help machines stay reliable. Cleaning, lubrication, and inspections stop breakdowns and keep production steady. Digital tools like CMMS help companies plan tasks and fix problems fast. If maintenance is ignored, machines break down and fills are wrong. Repairs cost more when care is missed. Good maintenance makes machines last longer and keeps products safe.

FAQ

What liquids can a filling machine handle?

Most filling machines work with water, juice, oil, and sauces. They also fill creams and chemicals. Some machines fill thick or chunky products. Buyers need to check if the machine fits the liquid’s thickness. They should see if it meets special needs.

How often should operators clean a liquid filling machine?

Operators clean machines every day or after each run. Regular cleaning keeps products safe. It stops clogs from happening. Some machines have Clean-in-Place systems. These make cleaning easier for workers.

Can one filling machine handle different bottle sizes?

Many machines can fill different bottle sizes. Operators change settings or parts for new containers. This helps companies save money. It lets them switch products quickly.

How long does it take to install a new filling machine?

Install time depends on machine size and how complex it is. Simple machines may take just a few hours. Big automated systems can take several days. Suppliers often help with setup and training.

English

English